Exact Fit

Vektor performance uses state of the art laser scanning and 3D modeling technology to ensure perfect alignment for easy installation. Our parts fit as well as or better than OEM.

Vektor Performance is a Porsche Performance Products company born from a recipe of Obsessive Engineering and Testing, Compulsive Fabrication, Craftsmanship, Highest Quality U.S sourced Materials, all Made in the USA. Our solution and performance based products are made with the goal of providing the Porsche market with the Best Available Bang-for-the-Buck Value, and include a Lifetime Warranty. Vektor Performance looks forward to contributing to your Success in Reaching Your Goals.

Vektor performance uses state of the art laser scanning and 3D modeling technology to ensure perfect alignment for easy installation. Our parts fit as well as or better than OEM.

Pushing performance to the next level while maintaining reliability is what sets Vektor apart from it’s competition.

All parts are designed and made in the United States.

Upon first inspection of the OEM manifold from Porsche we noticed that it is engineered as a solid reliable product; economical and easy to manufacturer. Two stamped and formed halves are welded to each other, a quarter inch three port flange, a turbine inlet tube, and finally another quarter inch flange that mounts to the turbo. These welds are robotic, and in some places the welds protrude inward reducing flow. The inside of the manifold is completely open, meaning there is no separation between the ports. This effectively makes the manifold one large turbulent plenum.

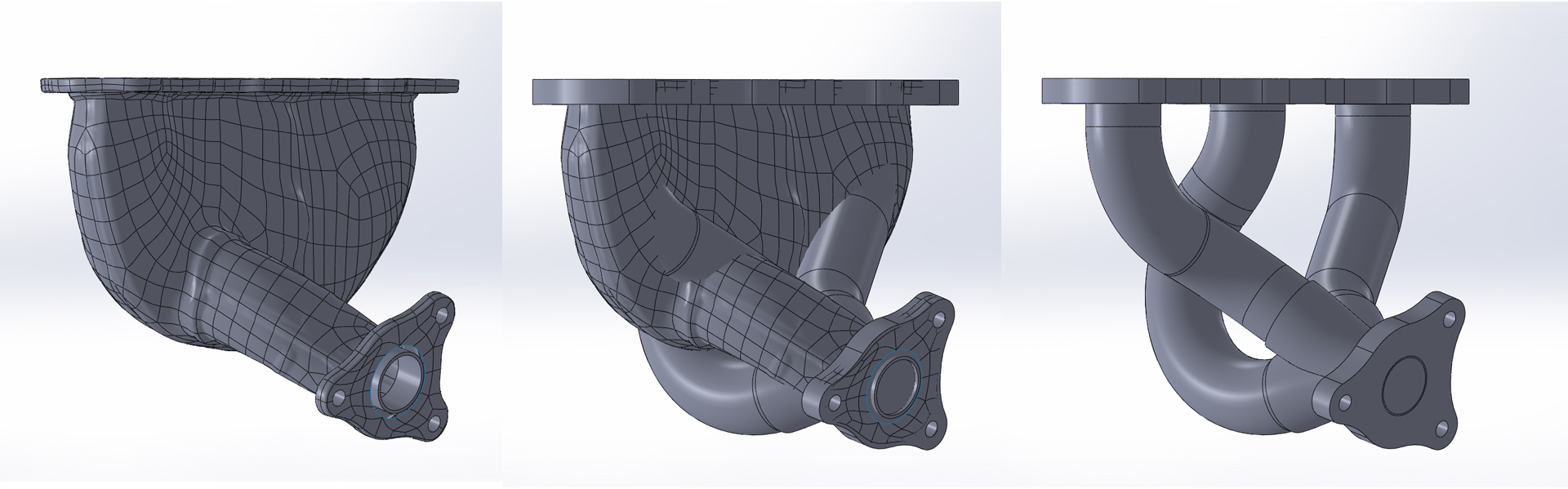

The OEM manifold is laser scanned and the data is transferred into our Solid modeling software. From this point the design flaws are adjusted. The manifold is morphed into individual primary tubes. Computer driven simulations are performed to test for both flow efficiency and stress resistant characteristics. Once an optimized performance design is reached the model is tweaked for reliable manufacturing processes that ensure quality, and then tested in the simulator again to ensure that no loss in strength or performance has occurred before a prototype is produced.

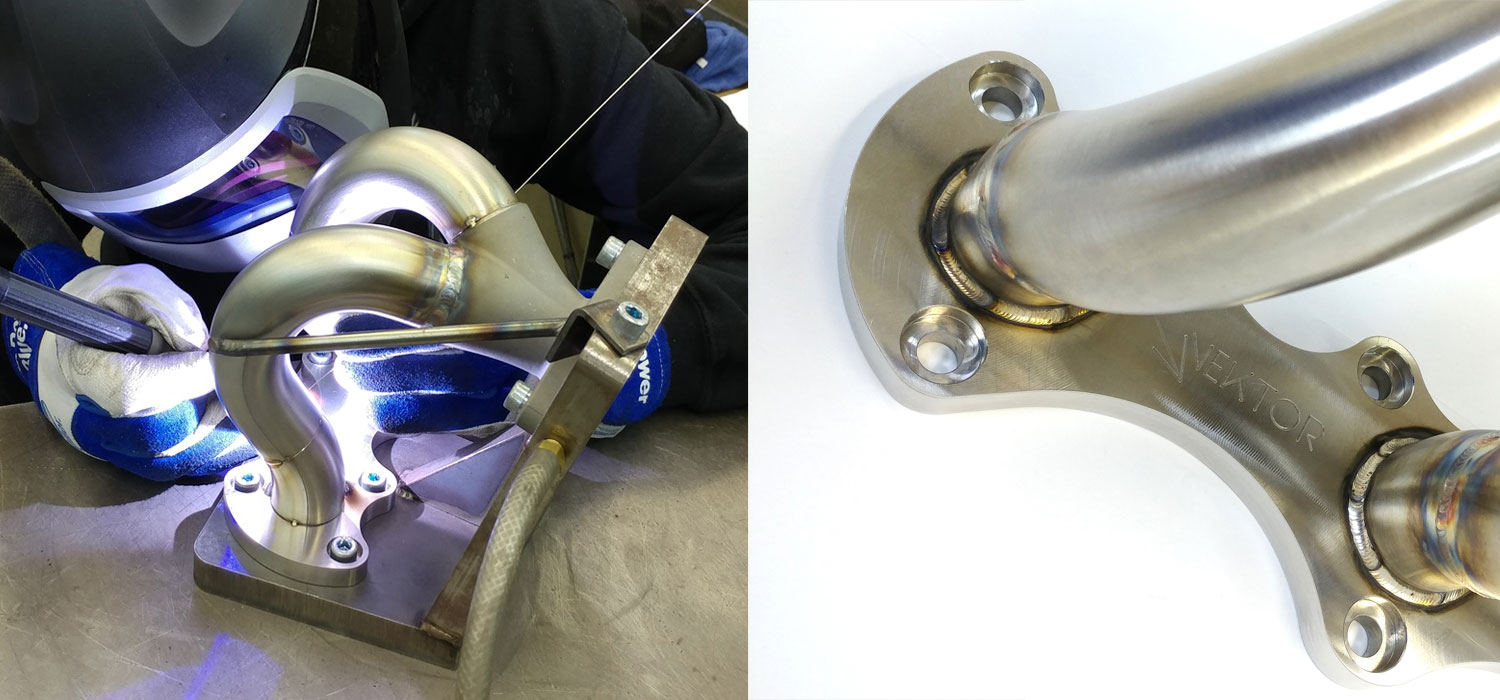

Our products and their components are made in the USA. 321 stainless steel is used in the construction of our headers for its superior thermal characteristics due to its alloying element titanium. Flanges are precision laser cut out of half inch stainless steel. The tubing is CNC mandrel bent ensuring no loss in diameter of the tube. The collectors are 347 stainless steel cast which is stable at high temperatures and aids in smooth merging from the primaries. All components are mounted in fixtures that provide back purging during the hand welding process which shields the welds on the inside of the header from impurities.

The final product design is put through extensive real world testing on the dyno, track and street until we have the utmost confidence that our header will improve the driving experience of our valued customers. Customers report that a typical installation of our header along with dyno tuning yields approximately a 30 HP gain. Your results may vary based on setup and the dyno / tune. Great care is taken with the production of our product, the selection of our materials, extensive testing, and quality control. You can feel confident purchasing Vektor Performance headers knowing that they are backed by our Lifetime Warranty.

Vektor Performance

1 Solution Way

Suite 201

Waynesboro VA

22980